The Laboratory of the Industry 4.0

Organizing an event like the Paperless Lab Academy requires strong project management skills, execution at its best and a lot of energy. However, the very best part of it is the outstanding opportunities to engage with so many active members of the lab informatics industry and its final users.

While discussing the content of their presentation or workshop for the #PLA2019 agenda, we definitely enjoy discovering people analysis on their today pains and their vision of the lab of the future.

Fact is that I’d like to share some of my thoughts out of so many conversations. When speaking to production and management, it is common to detect a lack of visibility of how the laboratory operates. Yet the expectations on quick and trustable results are omnipresent. It is also easy to generate attention when speaking about the Industry 4.0, automation, data exchange, Internet of things, cloud and more.

Who says that this is not also available for the laboratories too? Let´s do a small comparative exercise of how the industry and the laboratories have evolved through the technical revolutions.

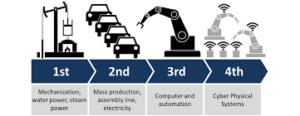

The first industrial revolution began through the use of steam power and mechanization of production

The first industrial revolution began in Britain in the late 18th century, with the mechanization of the textile industry. Tasks previously done laboriously by hand in hundreds of weavers’ cottages were brought together in a single cotton mill, and the factory was born.

Even though the evidence places Pythagoras of Samos´s home laboratory as the earliest laboratory. The pictures of Antoine Lavoisier laboratory are a good representation of the chemical laboratory used by his contemporaries in the 18th century. Additionally, the researcher started to work in teams in the 19th century along with exhaustive laboratory notebooks, the first definitions of standard operation procedures and stimulating scientific meetings sharing results and theories.

The second industrial revolution mastered the moving assembly line

The second industrial revolution came in the early 20th century when Henry Ford mastered the moving assembly line, and the age of mass production was born.

In the 20th century, the laboratory equipment was composed of highly precise glassware’s (Erlenmeyer flasks, graduated cylinders, volumetric flasks), controlled reagents, autoclave, personal protective equipment, measuring devices, extractor hoods, cold rooms, incubators, micropipettes and a long list of specialized instruments and devices. The mass production effect in the manufacturing lines can easily be compared to the scientific instruments. Those instruments are more complex in their role of performing an experiment, taking measurements and gathering data. They had the firmware communicating with a specific software for setup, configuration, raw data collection, and first results outcomes. The analysis of multiples samples in a row, plates of 96 and 384 wells and arrays have generated an incredible amount of data and permitted, for instance, the complete sequence of the human genome by 2003. The project per se started in 1990 and speed exponentially from 2000 with the launch of new analytical technologies, software and database capabilities, the era of the bioinformatics was born. Which brings us to the 3rd revolution.

The third industrial revolution made the manufacturing industry going digital.

Curiously, while the analytical instruments are generating an enormous amount of digital data and the internet of things enables the collection of data from multiple sources, the paper is still the main support of the laboratory processes. The measuring devices like balances and pipettes are generating information collected automatically and unequivocally. As an example, the IoT provides also very useful information controlling the sample storage conditions. Anyhow, we might say that most of the laboratories are still staying here, in the waves of the third industrial revolution. Too many chromatograms are still printed and attached to a dossier. There is a long way to go for the majority of the labs in moving from paper-based processes and in undergoing their own digital transformation process. However, the technologies, concepts, and objectives of the fourth industrial revolution are already here to serve the laboratory.

Four principles of the fourth industrial revolution

The fourth revolution gets the machines, devices, sensors, and people to connect and communicate within an Internet of things scenario and they cooperatively drive production. The principles: interconnection, information transparency, technical assistance, decentralized decisions. That is the vision for the Fourth Industrial Revolution.

Those principles are the ones making the laboratory 4.0 of today.

Technicians and analysts have the ability to connect and communicate with their analytical instruments, devices, and sensors. Above all, the automatic capture of the data is the essence of the so pursued data integrity compliance. Interconnectivity allows such transparency to managers that enables them to collect immense amounts of data and information from all points along the data lifecycle. To assist the data analysis, the systems support managers by aggregating and visualizing information comprehensively for making informed decisions.

In a production line, we would easily see the fourth revolution facilitating flexible, individualized and resource-friendly mass production. In a laboratory, the managers would benefit from systems making decisions on their own and performing their tasks as autonomously as possible, having them focusing only in the case of exceptions, interferences, or conflicting goals.

If ever a laboratory is able to focus human attention in what I like to call “review by exception” only, the Laboratory 4.0 is born.

At the #PLA2019, we´ll be discussing much more about the today and the future laboratory. How to turn the lab into a data-driven knowledge center will be central of the 7th edition.

Do not miss it! Registrations are free for visitors coming from companies that own a laboratory

Check out for more here: www.paperlesslabacademy.com